Nova Verta

Nova Verta International Spa is world-wide one of the most interesting reality in manufacturing spray-painting equipments with downdraft technology Made in Italy; its name, the acronyms of the Italian words verniciatura (painting), essiccazione (drying), riscaldamento (heating) e trattamento aria (air treatement), traces back to its Tuscan origin with an international breath.

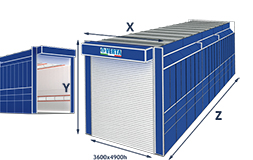

SPRAY BOOTHS

HIGH-PERFORMANCES FOR A PRODUCTIVITY UNLIKE ANY OTHER They are made with an obsessive attention to detail, both structural and technological, which guarantees high performance, essential to compete in such a competitive industry such as automotive.

INDUSTRIAL BOOTHS

To Suit All types of industrial spray finishing applications. Pressure, Suction and Gravity feed, the DeVilbiss Advance HD family utilise a comprehensive, wide range of Compliant Air Caps to provide outstanding coatings’ atomisation for handling all types of solvent, waterborne, high solids and 2K materials

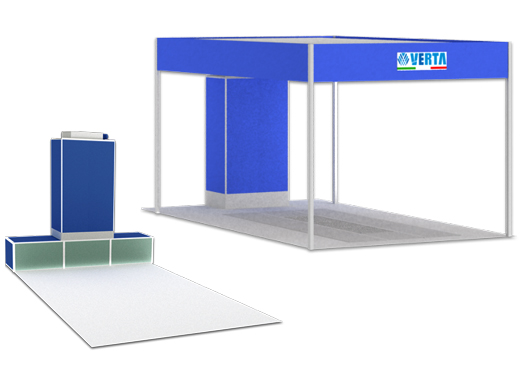

PREP STATION - HIGH SUCTION LEVEL

Using a variable frequency drive and make-up unit with a stainless steel heat exchanger, the Nova Verta system warms air and safely recirculates it through the Prep Station – without exposing operators or other shop employees to the dangers of carbon monoxide. No other prep station or paint booth provides a prep cycle that creates OSHA-mandated working conditions, heats the air, maintains air pressure, brings metal to the desired spray temperature, and generates monthly utility savings of 35% or more when compared to competitive systems in its class.

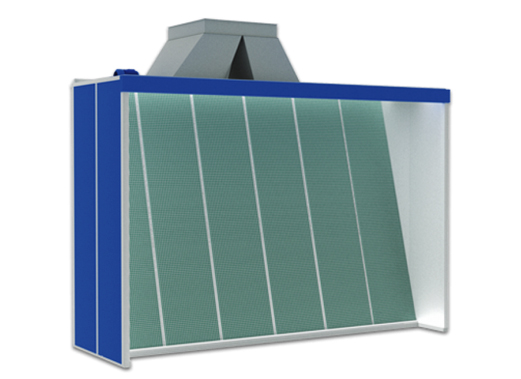

DRY CLEAN

THE IDEAL SOLUTION FOR THE PAINTING OF WOOD The Dry Clean is the solution studied to ensure high performances even in the carpentry sector and confirms Nova Verta competence and reliability.

MAKE UP UNITS

The generator group is a machine for the entry of air into the paint booths and/or working areas. The type of generator is chosen according to the requirements of air quantity in the spraybooth

EXHAUST UNITS

The exhaust unit is a machine for the extraction of air from spray booths and/or working areas. Possibility of dry, water or active carbon extractors.